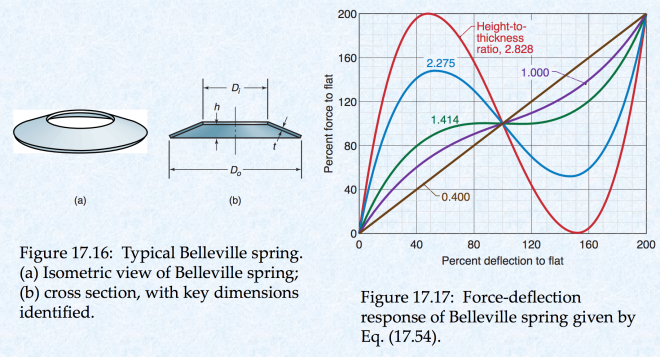

Belleville springs are conical washers that rely on the curvature of the shell to provide stiffness as it is compressed.

Bi-stable: Their geometry means that belleville spring can have a bi-stable snap-through behavior. This behavior can be very useful in mechanisms that we want to fail in a stable position, like this poppet valve: http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20090016268.pdf

From Fundamentals of Machine Elements by Schmid, Hamrock, and Jacobson

Hysteresis: Unlike helical springs, Belleville springs also generate friction as they deform because there is a coupled radial and axial motion at the outer and inner rim. This friction creates hysteresis in the spring’s force-deflection curve that (although it can inhibit repeatability) can also act as a damper if that is needed.

From NiTi Belleville washers: Design, manufacturing and testing, by Maletta et al.

Compact: Due to the non-linear nature of Belleville springs, it is possible to get a very large stiffness in a small volume. Additionally, Belleville springs can be stacked in series (like a bellows) to reduce their stiffness, or in parallel to increase their stiffness.

From Raymondasia

Information also taken from: https://en.wikipedia.org/wiki/Belleville_washer